Introduction

Supply chains have evolved into intricate worldwide networks throughout time. This makes supply chain management much more challenging.

Thank you for reading this post, don't forget to subscribe!Supply chain bottlenecks in the business lead to unhappy customers, higher operational costs, lesser profitability, and complex management processes. So, supply chain management is an essential function for businesses of all sizes.

According to a McKinsey survey, 93 percent of organizations planned to make their supply networks more flexible, agile, and resilient following the outbreak of COVID-19.

Supply chain optimization refers to increasing the effectiveness and efficiency of a company’s supply chain management operations. It includes examining and optimizing many aspects of the supply chain, including transportation, inventory management, warehousing, and manufacturing.

With an optimized supply chain, businesses can find bottlenecks, get rid of redundant information, and improve collaboration between many stakeholders by using supply chain optimization.

To find out more about how supply chain optimization can benefit your business, keep reading!

What is Supply Chain Optimization?

Your supply chain is more complicated than simply transferring things from point A to point B. It’s more like point A to point 12, with multiple divergent processes, unforeseen delays, and warehouse inventory issues in between.

However, what if things were different and your supply chain became a straightforward, efficient network?

Supply chain optimization improves the effectiveness of your supply network by utilizing complex technology such as artificial intelligence (AI), machine learning (ML), business intelligence, and business process management.

A high-performing supply chain increases business efficiency and responsiveness. This ensures that customers get what they want, when and when they want it, while also making the company profitable and contributing to supply chain sustainability.

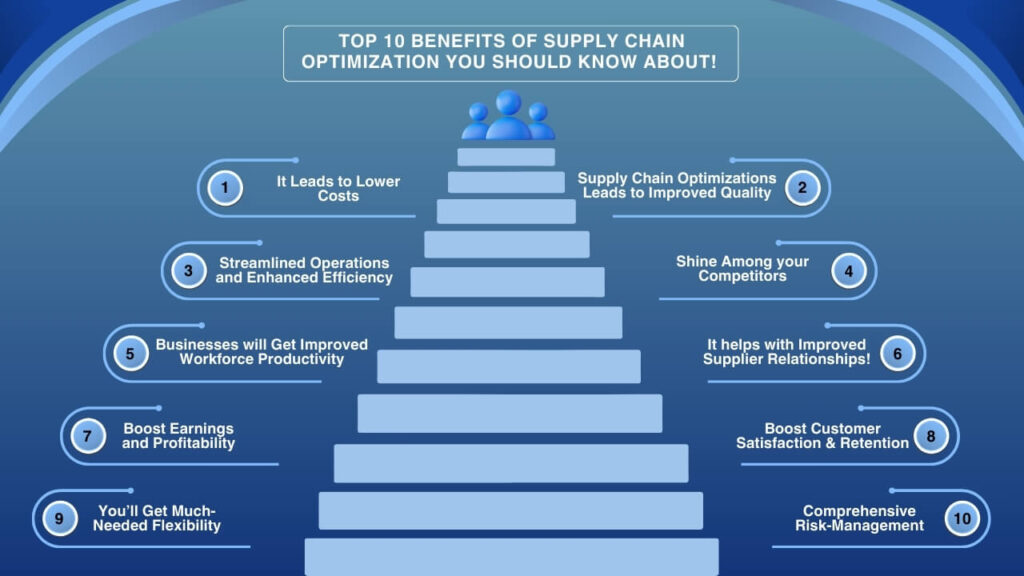

Top 10 Benefits of Supply Chain Optimization You Should Know About!

In today’s fast-paced market, not having an optimized supply chain means falling behind your competitors and losing out on growth and profitability. So, having a optimized supply chain is the need of the hour. Keep reading to know why with our 10 comprehensive benefits.

It Leads to Lower Costs

Supply chain optimization has several applications in which it can save expenses for a company. Infrastructure expenses can be better controlled and managed by streamlining the warehousing, logistics, and delivery operations.

In addition to streamlining their supply chain architecture, businesses can start automating procedures that are redundant, repetitive, and duplicate – which in turn can also lead to cost savings.

On top of it, increasing process efficiency results in direct savings in transaction execution and labor expenses. Moreover, supply chain cost optimization frees you up to concentrate on maintaining the ideal stock levels to satisfy consumer demands. As a result, the business incurs fewer inventory-related costs and has less unnecessary or abandoned stock.

Supply Chain Optimizations Leads to Improved Quality

Efficient supply chains maintain product quality from sourcing materials to delivering the final product. By optimizing the supply chain, managers uphold quality standards at every stage and prevent problems before they impact the end product.

For instance, quality managers develop inspection plans that focus on key points in the sourcing and assembly process. These plans catch issues early, such as low-quality materials or damaged components, allowing for quick corrective action.

When they identify a problem with sourced materials, they use the data to decide on the next steps, like revisiting the original specifications or checking if the supplier can meet the required quality.

AI management connects different systems, making it easier to adapt to changes and manage tight schedules. As the system gathers more data, it improves, ensuring consistent product quality from start to finish.

Streamlined Operations and Enhanced Efficiency

Supply chain optimization, with an emphasis on logistics management and third-party logistics, is critical for simplifying operations and increasing overall efficiency.

Businesses may identify bottlenecks, shorten lead times, and optimize transportation routes and inventory levels by employing data-driven insights and cooperating with experienced third-party logistics partners.

This streamlined strategy not only lowers operational expenses but also allows businesses to produce products more quickly and reliably, resulting in greater client satisfaction and a competitive advantage in the market.

Supply chain optimization allows the organization to streamline its logistics operations. The organization can cut transportation costs and lead times by optimizing routes, consolidating goods, and implementing effective warehousing solutions.

Shine Among your Competitors

Whether you are a restaurant owner, retail owner or own a fancy bar downtown – every business wants to do better than its competitors and would like to achieve a competitive edge. Well, optimized supply chains give businesses exactly the same.

According to supply chain expert, Hau Lee, “A well-optimized supply chain is not just about efficiency; it’s about creating a strategic advantage that drives competitive success.”

It gives businesses a competitive edge by enabling them to deliver products faster, reduce costs, and respond more effectively to market changes. When a supply chain is well-optimized, companies can outpace competitors by offering better service, maintaining lower prices, and adapting quickly to new trends or customer demands.

For example, if you run a downtown bar that’s famous for its craft cocktails and a new cocktail becomes popular overnight. With the proper supply optimization in place, you can swiftly adjust your orders and menu, while maintaining lower costs. This quick response and cost efficiency allow you to offer the latest trends and best prices, giving your bar a competitive edge over others.

Here’s the tip: To gain this advantage, businesses should focus on continuous improvement and innovation within their supply chain processes.

Businesses will Get Improved Workforce Productivity

Businesses are spending a large proportion of their expenses on recruiting and managing their staff. So, getting the most out of your investment is quite important. Well, an optimized supply chain helps to boost workforce productivity by making everything run smoother and more efficiently.

When processes are streamlined and automation is in place, employees can focus on the tasks that really matter instead of getting bogged down by repetitive or manual work.

For example, clear communication, higher automation, and streamlined processes mean the team spends less time fixing problems and more time on strategic activities. This not only helps them get more done but also makes their jobs more satisfying – which leads to higher employee satisfaction and lesser turnover. At the end, the higher employee satisfaction leads to improved customer assistance and satisfaction.

It helps with Improved Supplier Relationships!

A digitized supply chain harnesses technology to deliver real-time visibility into every aspect of supply chain operations. This continuous flow of data allows organizations to monitor performance, identify inefficiencies, and quickly address potential issues.

By ensuring that all suppliers to manufacturers to distributors—are connected and have access to the same data, businesses can ensure swift and accurate decisions. track supplier performance, manage contracts, and ensure compliance with quality standards.

Everyone is on the same page, which reduces delays and miscommunication. This approach also allows companies to track supplier performance closely, manage contracts efficiently, and ensure that all partners meet quality standards. The result is a more responsive, streamlined supply chain that operates smoothly and delivers better results.

Boost Earnings and Profitability

You can enhance the client experience by having a more efficient supply chain and automated customer care.

Supply chain optimization solutions help businesses deliver the proper order to the right customer at the right time. According to research, a 1% rise in sales is equivalent to a 2% gain in “perfect orders,” and a 2% improvement results in an additional 10 cents in earnings per share.

By streamlining the supply chain, you can respond more quickly and with significantly greater insight into all activities, which improves customer happiness and drives up reordering and customer retention.

Optimizing supply chain procedures improves end-to-end visibility and generates actionable data, allowing for faster reactions and a better customer experience.

This improves client retention and provides a competitive advantage, so increasing both the top and bottom lines.

Boost Customer Satisfaction & Retention

An optimized supply chain plays a crucial role in enhancing customer satisfaction and retention by ensuring that products are available when needed, and delivered on time, and meet high-quality standards. Efficient supply chain management allows businesses to provide a seamless and reliable experience for their customers, which is essential for building long-term loyalty.

- Consistent Product Availability: By maintaining optimal inventory levels and efficiently managing suppliers, businesses can prevent stock outs and ensure that the required products are always in stock. This reliability helps build trust with customers and adds to customer retention.

- High-Quality Products at Best Rates: An optimized supply chain helps maintain consistent high quality across products and services at the best rates for the customers because of real-time insights and streamlined communication and collaboration among suppliers and stakeholders.

- Efficient Problem Resolution: When issues arise, such as delays or product defects, an optimized supply chain allows for quick identification and resolution. This means businesses can address problems before they affect customers.

- Personalized Experience: An optimized supply chain provides data-driven insights into purchasing behavior and preferences. Businesses can use this information to tailor their offerings and marketing efforts to boost customer satisfaction, and retention and get the maximum ROI.

- Enhanced Communication: Effective supply chain management improves communication between the business and its customers. Timely updates about order status, delivery times, and product availability help keep customers informed and engaged. For instance, an online store with a well-optimized supply chain can provide accurate tracking information and updates, making the shopping experience more transparent and satisfying.

- Seamless Omnichannel Experience: An optimized supply chain supports a smooth experience across different shopping channels—whether online, in-store, or via mobile apps. This consistency makes it easier for customers to shop however they prefer.

You’ll Get Much-Needed Flexibility

In this fast-paced world, you need to cope with changing markets and customer preferences. It is not a choice, but a necessity. Well, an optimized supply chain gives businesses the flexibility they need to adapt quickly to changes, whether it’s a sudden spike in demand, market shifts, or unexpected disruptions like supplier delays or material shortages.

By leveraging real-time data and efficient processes, companies can promptly adjust production schedules, manage inventory levels, and respond to customer needs without significant delays. This adaptability ensures that businesses can keep operations running smoothly, even when things don’t go as planned.

For instance, let’s consider a restaurant that typically serves a steady number of customers but suddenly experiences a surge in reservations due to a local event. Without the optimized supply chain system and its flexibility, the restaurant might run out of key ingredients or face delays in service, leading to unhappy customers.

But, with an optimized supply chain, the restaurant can quickly adjust by ordering more ingredients, coordinating with suppliers to get fresh produce delivered sooner, and increasing staff to handle the extra demand. This improves customer satisfaction, boost revenue, boost customer retention and increase overall bottom line.

Comprehensive Risk-Management

In businesses, effective management of risks are quite important. Optimized supply chain management helps with the same.

- With real-time data and advanced analytics, companies can monitor every part of their supply chain— from inventory levels to supplier performance and customer demand. This constant flow of information helps them spot issues like potential delays from suppliers or sudden increases in demand before they escalate into major problems.

- Having this early visibility allows businesses to proactively plan and implement solutions. For instance, if a supplier is likely to face delays, the company can arrange alternative suppliers or increase safety stock to prevent shortages. If there’s a sudden spike in demand, they can adjust their production schedules or reroute shipments to ensure timely delivery.

Walmart is a great example of how an optimized supply chain can enhance risk management.

The retail giant uses advanced technology and data analytics to monitor its supply chain in real-time. For instance, during the COVID-19 pandemic, Walmart has to deal with increased demand for certain items like cleaning supplies and groceries. Thanks to their optimized supply chain, they were able to rapidly adjust their inventory and logistics to meet the surge in demand.

They communicated effectively with suppliers, rerouted deliveries, and ensured that stores were stocked appropriately. This proactive approach helped Walmart manage risks effectively, keep shelves stocked, and maintain customer trust throughout the crisis.

AI for Supply Chain Optimization in Businesses!

Artificial Intelligence (AI) in supply chain management is a paradigm change that transforms responding to operational difficulties into proactive initiatives, not merely improving the effectiveness of the industry.

According to a McKinsey study, AI-powered solutions can cut supply chain failures by 20% to 50%, which can result in a 65% reduction in missed product orders. With a large amount of data, artificial intelligence (AI) may find patterns and extract new information from seemingly unconnected data sources.

As per Gartner, by 2025, AI-driven systems will be used to make 25% of decisions in the supply chain sector. Insights from these systems’ data aid in automating routine procedures, integrating previously unintegrated systems, and increasing supply chain efficiency.

To Conclude

Supply chain is the backbone of every business and optimizing it to the fullest that helps you streamline your business operations and boost revenues is quite important.

As we have stated, supply chain optimization has lots of benefits – but the task is not that easy. It is quite resources extensive – be it money, time, efforts and what not. But, AI and the best AI tools makes it all possible.

If you are looking for one, Livelytics has got you covered. It is a leading AI data platform enriched with sophisticated technologies and features will make the work the extensive and tedious task of supply chain optimization easier for businesses in restaurant, salon, retail and hospitality industry.

If you would like to check out how Livelytics can help you out, book a free demo and check out for yourself. Looking forward to hearing from you!